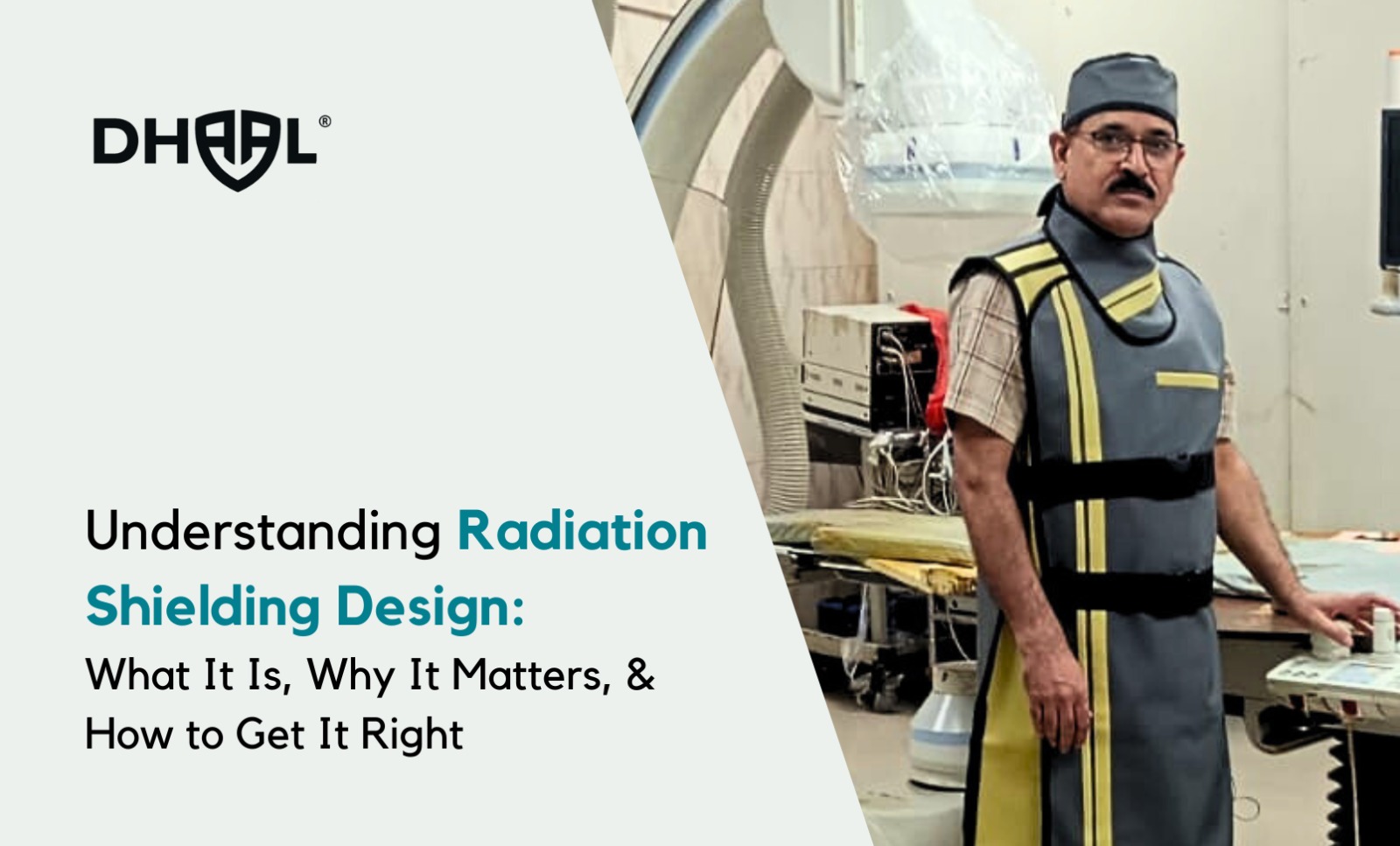

Radiation shielding design plays a crucial role in safeguarding individuals and equipment from harmful radiation. Whether you’re working with nuclear energy, medical equipment, or any industry involving radiation, understanding how to design effective shielding is essential for safety and compliance. In this blog, we’ll dive into what radiation shielding design is, why it matters, and how to get it right.

What Is Radiation Shielding Design?

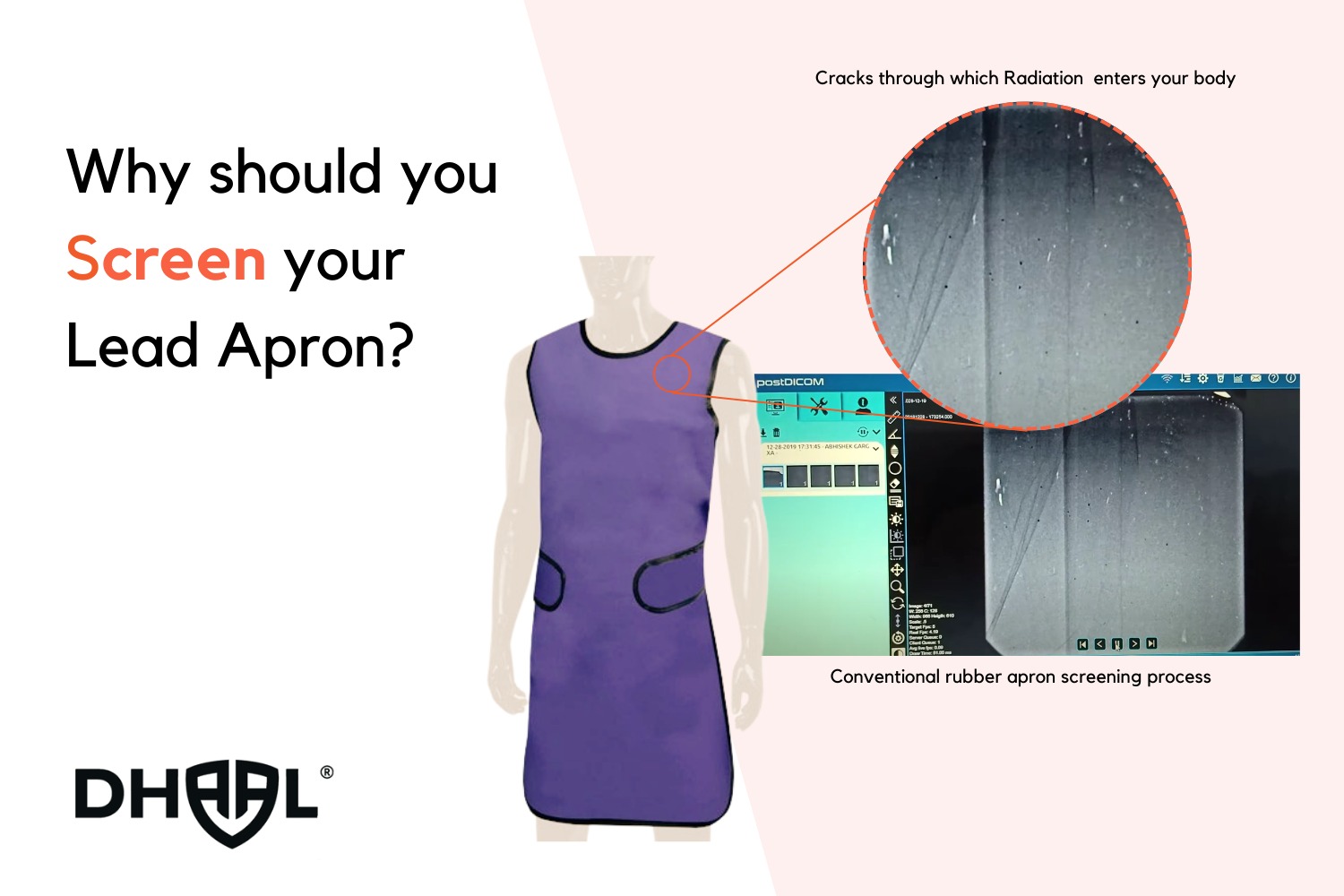

Radiation shielding design refers to the process of creating barriers that prevent or reduce the transmission of radiation. These barriers can take various forms, such as physical walls, lead sheets, or specialized materials that absorb, reflect, or scatter radiation. The primary goal of radiation shielding is to protect people, the environment, and sensitive equipment from the harmful effects of radiation exposure.

Different types of radiation (such as alpha, beta, gamma, or neutron radiation) require specific shielding strategies. For instance, gamma rays require dense materials like lead, while alpha particles can often be blocked by a sheet of paper.

How to Get Radiation Shielding Design Right

- Understand the Type of Radiation: The first step in designing effective shielding is understanding the type and intensity of radiation involved. Alpha particles, beta particles, gamma rays, and neutrons each interact with materials differently. The shielding requirements for each type vary, so a deep understanding of the radiation in question is necessary.

- Use the Right Materials: Different materials provide different levels of shielding effectiveness. Lead is commonly used for gamma and X-rays due to its density and ability to absorb radiation. For neutron shielding, materials like borated polyethylene are often used. The choice of material depends on the type of radiation, the level of protection required, and the specific needs of the project.

- Consider Thickness and Density: The effectiveness of a shield is often proportional to its thickness and density. For instance, thicker and denser materials typically offer better protection. However, there are practical limits to how thick a shield can be, especially in situations where space is limited or the weight is a concern. A balance must be struck between effective shielding and practicality.

- Understand the Concept of Shielding Effectiveness: Shielding effectiveness is measured by the reduction in radiation intensity after it passes through a material. This can be quantified using a term called the “half-thickness” – the thickness of a material required to reduce radiation intensity by half. Understanding these calculations helps in determining the minimum shielding required to meet safety standards.

- Design for Practicality: In addition to offering protection, radiation shielding must be practical. It must not impede the normal operation of equipment or restrict movement. For example, while thick shielding may provide excellent protection, it could also limit accessibility or the functionality of the equipment. Designers need to ensure that the shielding does not interfere with operational efficiency.

- Regular Maintenance and Monitoring: Radiation shielding is not a one-time solution. Over time, materials may degrade or become less effective, so regular maintenance and monitoring are essential. Periodic checks ensure that shielding continues to meet safety standards and that any issues are addressed promptly.

Conclusion

Radiation shielding design is a complex but critical process that ensures the safety of individuals, the environment, and sensitive equipment from the harmful effects of radiation. By understanding the type of radiation, selecting the appropriate materials, and considering practical aspects, effective shielding can be achieved. Whether you’re working in healthcare, nuclear energy, or any other field involving radiation, getting the design right is essential to minimize risks and maintain regulatory compliance.

Always consult with experts and adhere to industry standards to ensure that your radiation shielding design is safe, effective, and sustainable in the long run.