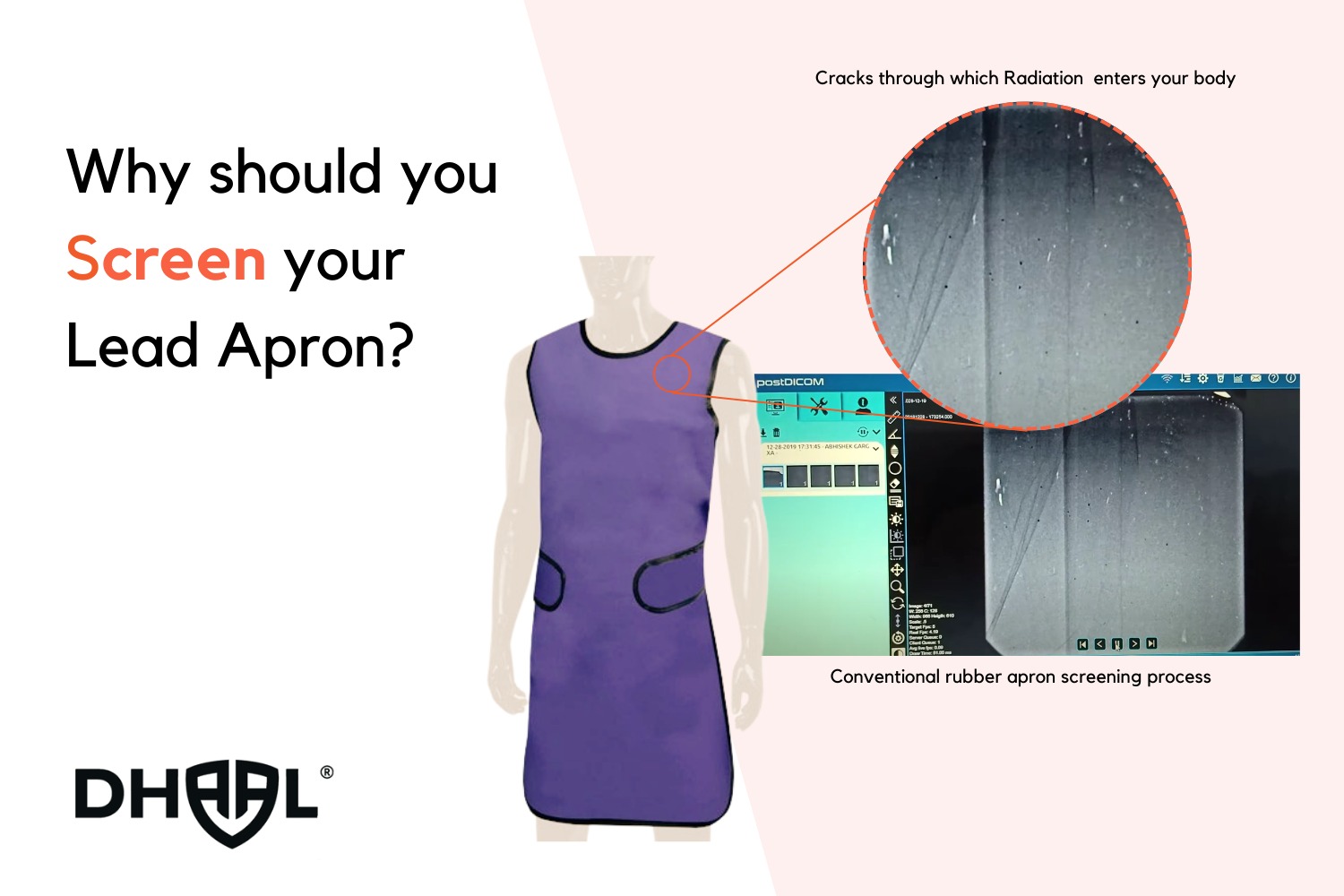

Regular lead apron inspection is crucial for ensuring the safety of medical personnel and patients in healthcare facilities. Most often, regular Lead Aprons are a combination of rubber and lead. Rubber has the tendency to get hardened with change in temperature and humidity levels. The cracks or imperfections inside the protective sheet are not visible to the naked eye, until the cracks become so large, that the sheet breaks inside the top cloth layer. It is important to identify small cracks or patches through which radiation might be penetrating because:

- Radiation Protection: Lead aprons are used to shield medical personnel and patients from harmful radiation during medical imaging procedures such as X-rays, CT scans, and fluoroscopy. Regular inspection ensures that the aprons are free from damage or defects that could compromise their effectiveness in blocking radiation.

- Durability: Lead aprons can deteriorate over time due to wear and tear, exposure to radiation, and improper handling or storage. Regular inspection allows for the detection of any signs of damage or degradation, enabling timely repairs or replacements to maintain the aprons’ integrity.

- Compliance: Healthcare facilities are typically required to adhere to strict regulatory standards regarding radiation safety. Regular inspection of lead aprons helps ensure compliance with these standards, minimising the risk of regulatory violations and associated penalties.

- Risk Reduction: Failure to properly inspect lead aprons can result in undetected damage or defects, increasing the risk of radiation exposure for both medical personnel and patients. By identifying and addressing issues proactively, regular inspection helps mitigate this risk and promotes a safer working environment.

- Cost Savings: Timely identification and repair of damage in external cloth stitching, velcro pasting etc. can be repaired preventing the need for costly replacements. However, any damage on the protective sheet will require it to be replaced by a new apron. Investing in regular inspection can ultimately save healthcare facilities money in the long run.

- Peace of Mind: Knowing that lead aprons have been regularly inspected and are in good condition provides peace of mind to both medical personnel and patients. It instills confidence in the safety measures implemented within the healthcare facility, fostering a culture of safety and trust.

In summary, regular lead apron inspection is essential for maintaining radiation safety, ensuring regulatory compliance, reducing risks, saving costs, and promoting peace of mind in healthcare settings