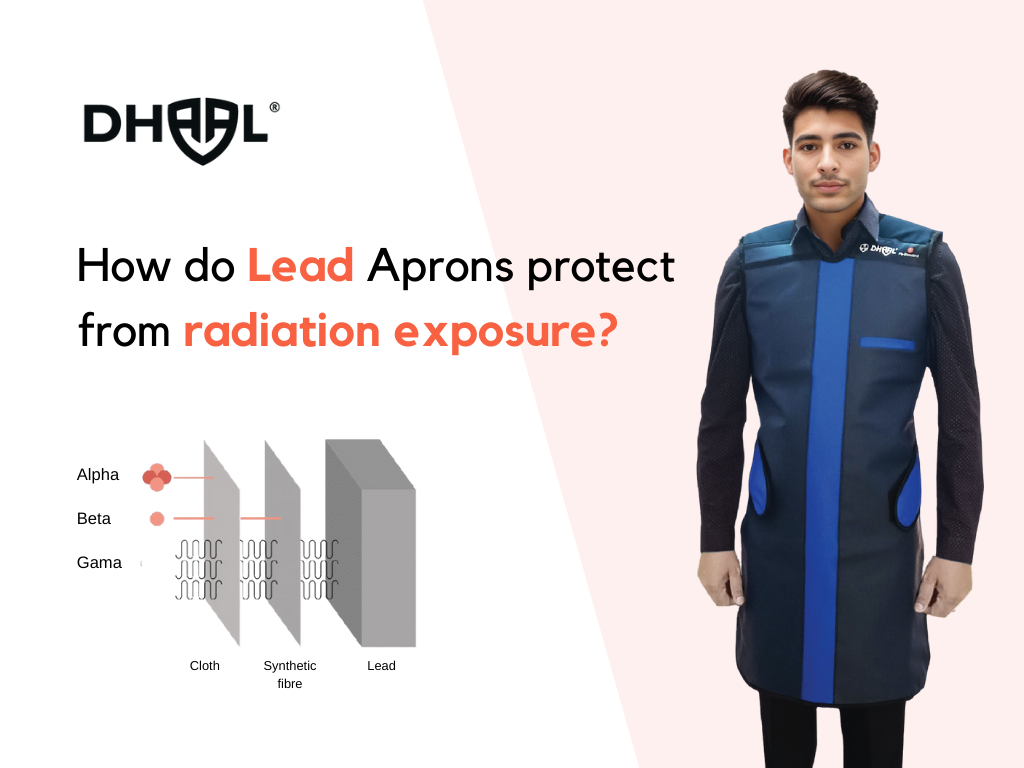

Quality assurance of lead aprons for radiation protection is essential to ensure that these garments effectively shield individuals from harmful radiation exposure during medical procedures. Here are some key aspects of quality assurance for lead aprons:

- Material Quality: The lead-impregnated material used in the apron should be of high quality and meet specified standards for radiation protection. It should provide adequate shielding against ionizing radiation while maintaining flexibility and durability.

- Lead Equivalence: Lead aprons are rated based on their lead equivalence, which indicates the level of radiation protection they offer. Quality assurance measures involve verifying that the lead aprons meet the required lead equivalence standards specified by regulatory bodies such as the International Electrotechnical Commission (IEC) or the American National Standards Institute (ANSI).

- Manufacturing Standards: Lead aprons should be manufactured according to standardized procedures and quality control protocols to ensure consistency and reliability. Manufacturers should adhere to relevant industry standards and guidelines for the design, construction, and testing of radiation protection garments.

- Product Testing: Quality assurance processes typically involve rigorous testing of lead aprons to evaluate their performance and effectiveness in shielding against radiation exposure. This may include testing for lead equivalence, durability, flexibility, and resistance to wear and tear.

- Certification and Compliance: Lead aprons should be certified by regulatory authorities or third-party organizations to ensure compliance with safety standards and regulations. Certification provides assurance that the aprons have undergone testing and meet specified requirements for radiation protection.

- Proper Fit and Sizing: Ensuring that lead aprons fit properly and provide adequate coverage is crucial for effective radiation protection. Quality assurance measures may involve verifying that the aprons are available in various sizes and adjustable to accommodate different body types.

- Maintenance and Inspection: Regular maintenance and inspection of lead aprons are essential to detect any signs of wear, damage, or degradation that could compromise their effectiveness. Quality assurance protocols may include guidelines for proper care, storage, and inspection of radiation protection garments.

Overall, quality assurance of lead aprons for radiation protection involves comprehensive testing, certification, and adherence to industry standards to ensure that these garments effectively shield individuals from radiation exposure during medical procedures.